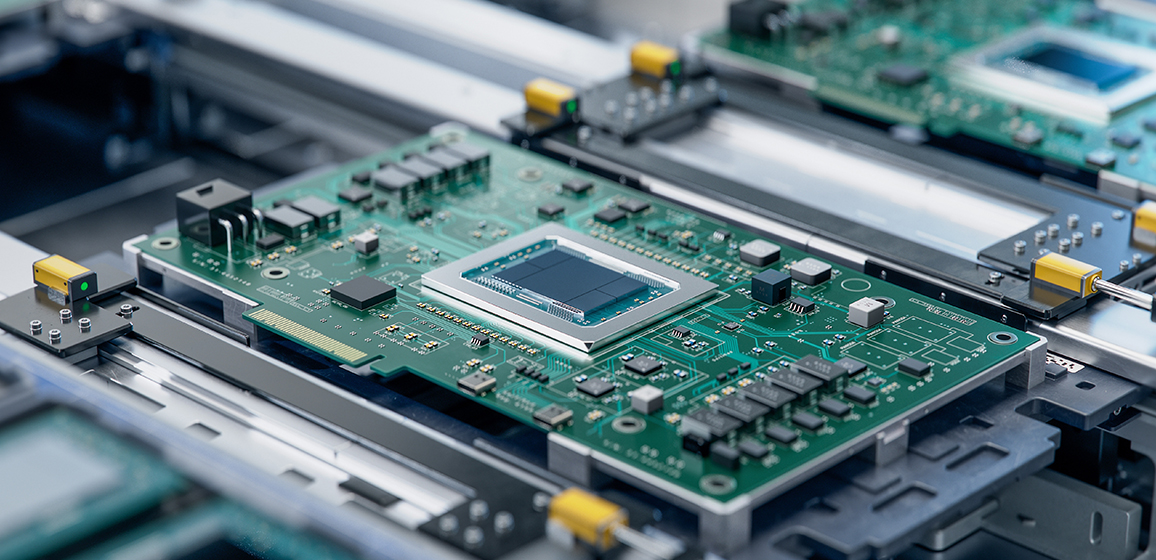

Technological Advancements and Process Optimization in PCB Manufacturing #

The Printed Circuit Board (PCB) industry has experienced rapid transformation in recent years, driven by the demand for smaller, more complex electronic devices. This article explores the evolution of PCB technology, the challenges faced in production, and the strategies manufacturers employ to optimize processes and remain competitive.

The Role of PCBs in Modern Electronics #

Printed Circuit Boards are fundamental to all electronic devices, serving as the backbone that connects components such as displays, batteries, memory, storage, modems, camera modules, and sensors. These elements are mounted onto the PCB, which provides the necessary electrical connections for integrated operation. As devices become more compact and powerful, PCB designs must accommodate increasingly dense and intricate circuits.

Evolution of PCB Technology #

The development of PCBs has progressed from traditional single-sided, double-sided, and multi-layer boards—used in basic electronics like calculators and computer motherboards—to advanced high-density interconnect (HDI) boards. HDI boards feature more layers in smaller footprints, while rigid-flex boards utilize flexible PCBs to connect multiple HDI sections, enabling three-dimensional configurations within devices.

A significant advancement is the ‘any layer HDI’ technology, which allows connections between any circuit layers, offering greater design flexibility and further miniaturization. Additionally, Substrate-Like PCBs blend PCB and integrated circuit packaging technologies, pushing the boundaries of circuit density and performance.

Challenges in PCB Production #

With each new generation, PCBs become smaller and more complex, requiring precise control over line width and spacing. Each layer of a PCB may demand unique process parameters, such as specific flow rates and spray pressures. To ensure reliability and repeatability, manufacturers employ variable frequency drives (VFDs) to control pumps and continuously monitor and adjust process parameters for stability.

Advanced Process Controls and Automation #

Modern PCB manufacturing relies heavily on automation to manage the multitude of variables in each production step. However, automation alone is not sufficient. Continuous feedback systems are essential to detect deviations—such as changes in spray pressure due to a malfunctioning nozzle—and alert operators or control centers promptly. This feedback loop minimizes production losses and maintains product quality.

Production Environment Improvements #

Traditionally, PCB factories used open plating tanks, exposing workers to corrosive fumes. Today, most processes occur within enclosed or environmentally controlled equipment, significantly improving workplace safety. As circuit features shrink, controlling dust and maintaining a clean environment become critical. Modern facilities are climate-controlled, with limited on-site personnel to reduce contamination and heat. Equipment is designed for reliability and leak-free operation, supporting preventive maintenance and minimizing downtime.

Strategies for Cost Competitiveness #

The PCB market is highly competitive, making cost control and high yield rates essential. Manufacturers can enhance competitiveness through several strategies:

-

Utilize High-Efficiency Equipment: Energy efficiency is a key focus. Since production lines integrate various technologies—pumps, heat exchangers, conveyors—collaboration with system designers and component manufacturers is vital to identify energy-saving opportunities.

-

Consider Life-Cycle Costs (LCC): Evaluating the total cost of equipment over its lifetime—including purchase, installation, operation, maintenance, downtime, and decommissioning—provides a clearer picture of long-term value. For example, operational costs often dominate the LCC of chemical pumps, with maintenance and downtime also playing significant roles.

-

Prioritize Equipment Durability: PCB process equipment typically has an average lifecycle of about eight years. Components that match or exceed this lifespan, such as durable chemical pumps, offer better value by reducing replacement frequency and associated costs.

Related Solutions and Further Information #

With extensive experience and customization capabilities, we assist companies in identifying the most suitable solutions for their PCB manufacturing needs. For more details or tailored advice, please contact us.